Air Filtration & Planer Cart

***RETIRED: September 2018***

I really wanted to capture as much of the dust in the air of my workshop as I could. Breathing in fine dust particulates over many years is simply not healthy. I had a small JET AFS-500 tabletop air filtration unit (no longer available) that I purchased when I had a small workshop in our basement in Maryland. It served me well for the small space that I had at the time. However, given the size of the garage in use now, it alone would not be able to handle the volume. I wasn’t too keen on the prices of the air filtration units I was looking at from most manufacturers, so I figured I could maybe make something instead.

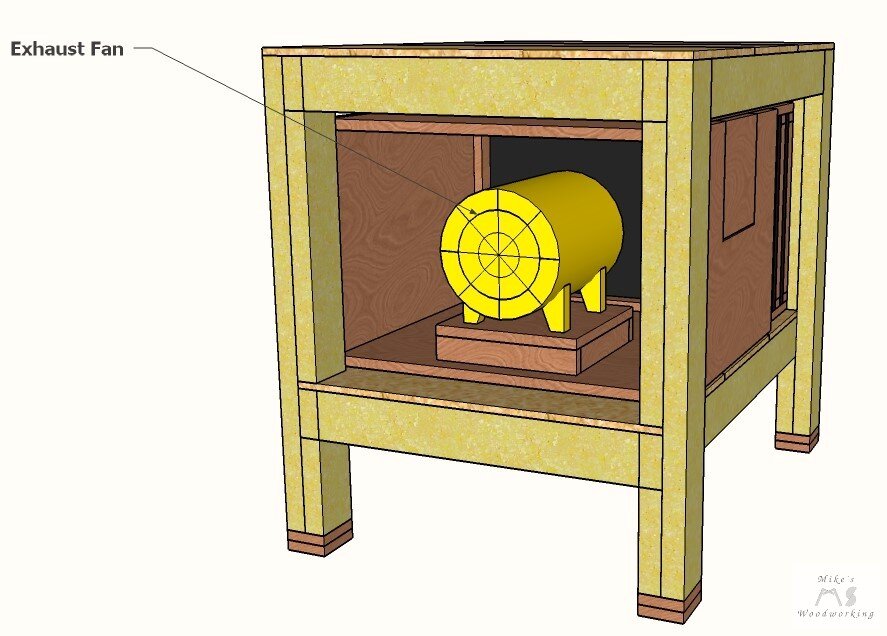

Jay Bates at Jay’s Custom Creations, along with Shawn Stone from Stone & Sons Workshop, showed how to make one using an old heat pump squirrel-cage motor. I didn’t have access to such a motor, and I wasn’t comfortable with my knowledge on such motors, so I found an air mover fan that could be used for a variety of tasks. I would simply make a box into which the fan would fit and build in slots for a three-stage filter setup. As a two for one build, the top surface of the cart would be used for my DeWalt planer.

The build wasn’t anything spectacular or complicated. The hardest part was figuring out a way to run the power cord from the fan to outside of the box, still have access to the fans on/off switch and not have any air leaks. The system I devised seemed to work well enough. I would simply have a hinged access door on one side of the box, some foam gasket around the opening, and a bungee cord to hold the door closed tight.

The overall dimension of the air filtration unit was quite large, meaning the cart itself was quite large (I probably would have made the air filtration unit a bit smaller, in retrospect). It worked for the six months or so that I had it in service, but I ultimately was not satisfied with it. Along with the fan being much louder than I was expecting, even on its low setting, the overall footprint was just too much. I opted to just bite the bullet and get the JET AFS-1000B I had been researching months prior. It wound up being smaller, much quieter and it meant I could get rid of the monstrous cart. My only problem was where was I going to put the new air filtration unit, because it wasn’t going inside the cart. I was keeping the cart only temporarily to still have a place for the planer.

The ceiling is comprised of the bottoms of trusses that support the roof, not joists that are used to support another floor of a house. It is my understanding that the trusses were not designed to support large amounts of weight hanging from the bottom. This posed a problem as the air filtration unit was a bit heavy, not to mention hanging it from the 9 ½ foot ceiling was going to be a challenge in and of itself anyway. After taking a long look at the shop, I noticed a perfect place...the top of my miter saw station.

Now, that still presented a bit of a problem as the top of the miter saw station was a good six feet off of the floor. I did, however, have a secret weapon up my sleeve. I still had a lift cart that we bought before we moved to Florida. It was originally used to lift, lower and move the heavy and awkward top half of our bedroom armoire. With the lift table all the way down, it just squeezed under the bottom shelf of the planer/air filtration cart (not by original design, but I’ll take this happy accident). With the JET unit placed on the top of the planer cart, and the lift table maxed out with its height, this put the JET unit at almost the same height as the miter saw station. It was just a matter of slowly sliding it off of the cart and onto the miter saw station. I made a dry run before trying it, so I knew it would work. Everything worked like a champ and the air filtration is now in its final place and it has not moved since. The cart was ultimately taken apart and reused for other things, but not before I needed something to replace it in order to hold the planer.